Cobot Palletizing Software

Build, save, and recall custom pallet layouts without writing a line of code.

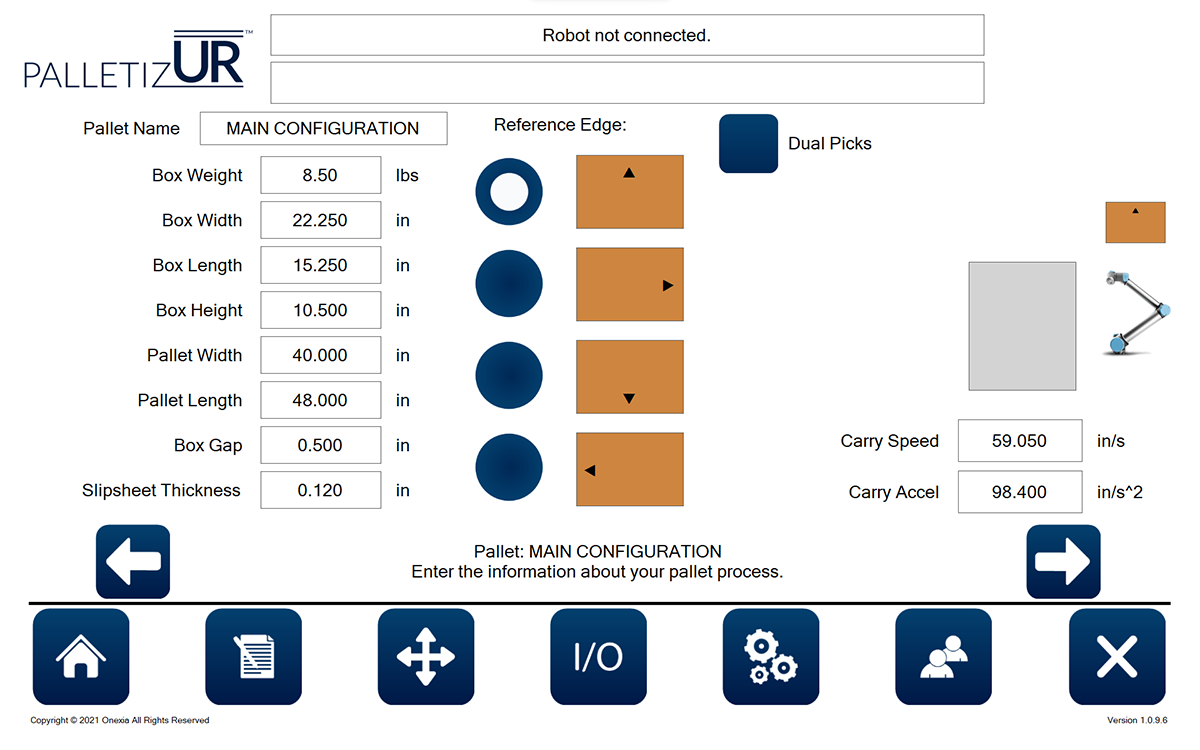

Designed by ONExia Inc., the ONExia Palletizing Software provides complete control of the palletizing cell through a touchscreen interface.

No Teach Pendant Needed

Ideal for non-technical staff, the PalletizUR eliminates the cobot teach pendant providing a simplified user experience.

- Simplified interface - control the entire system through a single touchscreen

- Drag-and-drop software - build pallets with no programming needed

- Pallet library - easily save and recall different pallet configurations based on production demands.

- Administrative controls - limit system access based on user credentials

Palletizing with Universal Robots

The PalletizUR is not a kit.

Using the OEM version of the Universal Robots 10e, UR20, or UR30 cobot arm, each system is delivered production ready with no assembly or development time needed.

Free-drive Enabled

Using the free-drive abilities of Universal Robots cobots, end-users can manipulate the robot by hand when teaching the pick and place locations needed to build a pallet configuration.

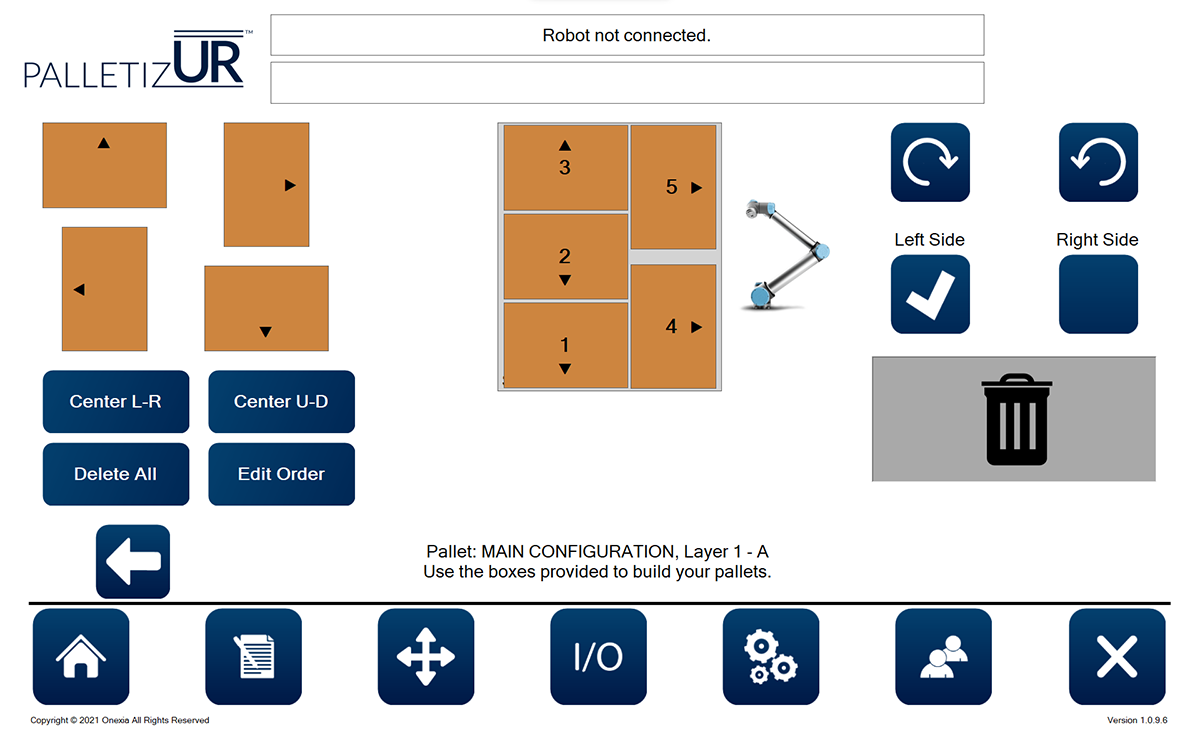

Drag-and-Drop Pallet Building

The PalletizUR keeps downtime to a minimum by providing a step-by-step pallet building experience without writing a line of code.

1. Enter Dimensions

2. Drag & Drop Box Positions

3. Organize Pallet Layers

4. Teach Pick Position

Advanced Palletizer Functionality

Designed by an experienced robotics integrator, the PalletizUR can be easily configured to the specifics of your application.

Slip Sheets

Easily add slip sheet layers to your pallets within the embedded software.

Label Orientation

Keep shipping labels oriented correctly for scanning during final shipment.

Upstream Automation

Control nesting conveyors, barcode readers, and reject stations within the palletizing software.