Collaborative Palletizer

A robotic palletizer is a robotic cell that is designed to stack boxes and other standardized products onto a pallet for final shipment. By using collaborative robots for palletizing, reliable workers can focus on the value-added tasks upstream in the manufacturing process.

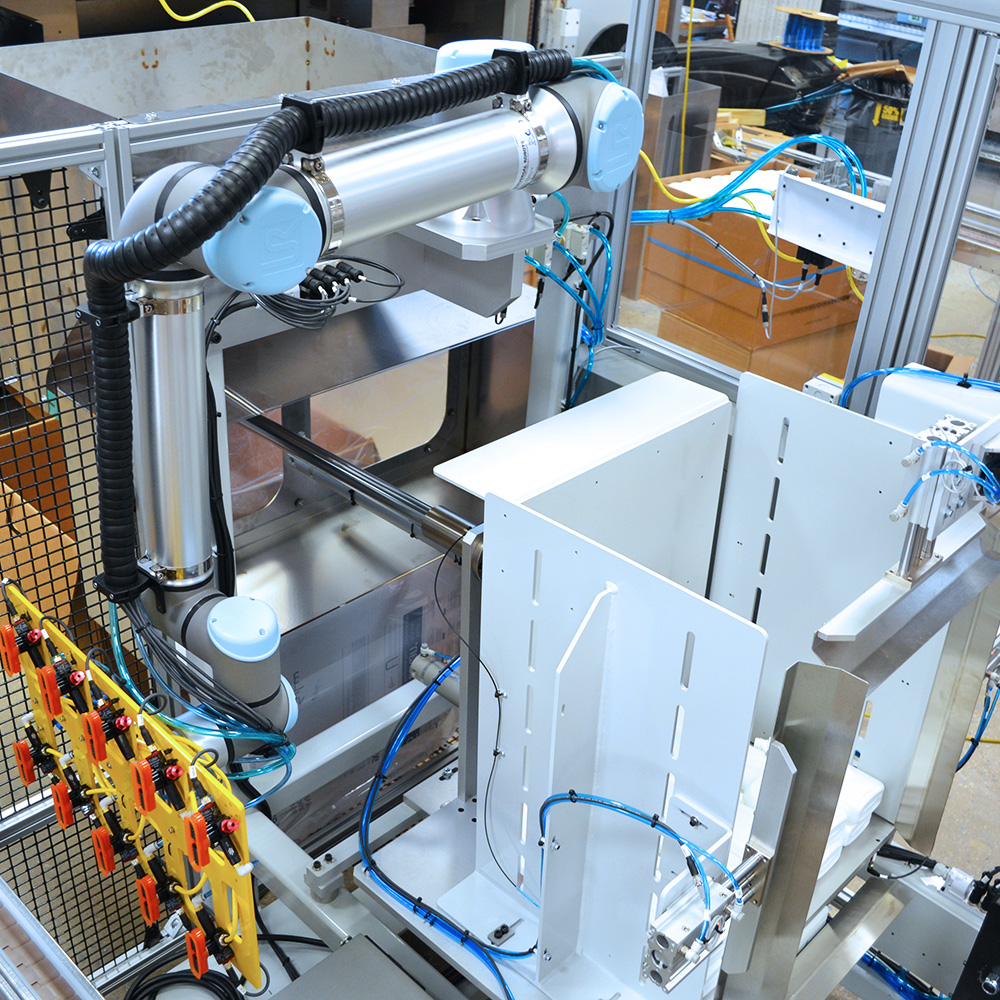

Introducing the PalletizUR

The PalletizUR is a simplified robotic palletizer. Controlled through a touchscreen interface, non-technical operators can add, edit, and save pallet configurations without writing a line of code.

Palletizing with a collaborative robot

Being collaborative means it works alongside workers, no caging or guarding required!

Third party verified to meet industry standards, the PalletizUR is a compact alternative to traditional palletizing machinery.

Flexible Palletizing System

Invest in technology that adapts to future demands. Designed for lines running various case sizes, the PalletizUR is easily adjusted for product changeover.

Durable and Portable

Minimal Integration

Custom End Effectors

PalletizUR Software

Continuous Operation

Auto-Height Adjustment

Cobot Palletizing Software

Automate palletizing using a collaborative robot without writing a line of code.

No engineering degree needed

The ONExia Robotics palletizing software provides complete control of the palletizing cell through a single touchscreen interface.

- Drag-and-drop software - build pallets with no programming needed

- Pallet library - save and recall pallets from a dropdown menu

- Simplified usability - hardware, robot, and safey devices are all controlled through a single touchscreen

Robotic Packaging Systems

Cost-effective solutions for automating the dull, repetitive, and ergonomically challenging tasks on packaging lines.

- Turn-key packaging lines using cobots

- Case erectors, case packers, & custom conveyors

- End-of-arm gripper and tooling design

- Minimal footprint - automate existing lines!